Today’s drilling environment involves challenges previous generations rarely faced, if ever. From deeper, harder-to-access deposits to operational challenges with automated rod handlers to tighter margins from a more competitive and volatile global mineral exploration market, today’s driller needs efficient solutions to difficult situations.

Drilling has changed – have your drill rods changed to meet these challenges?

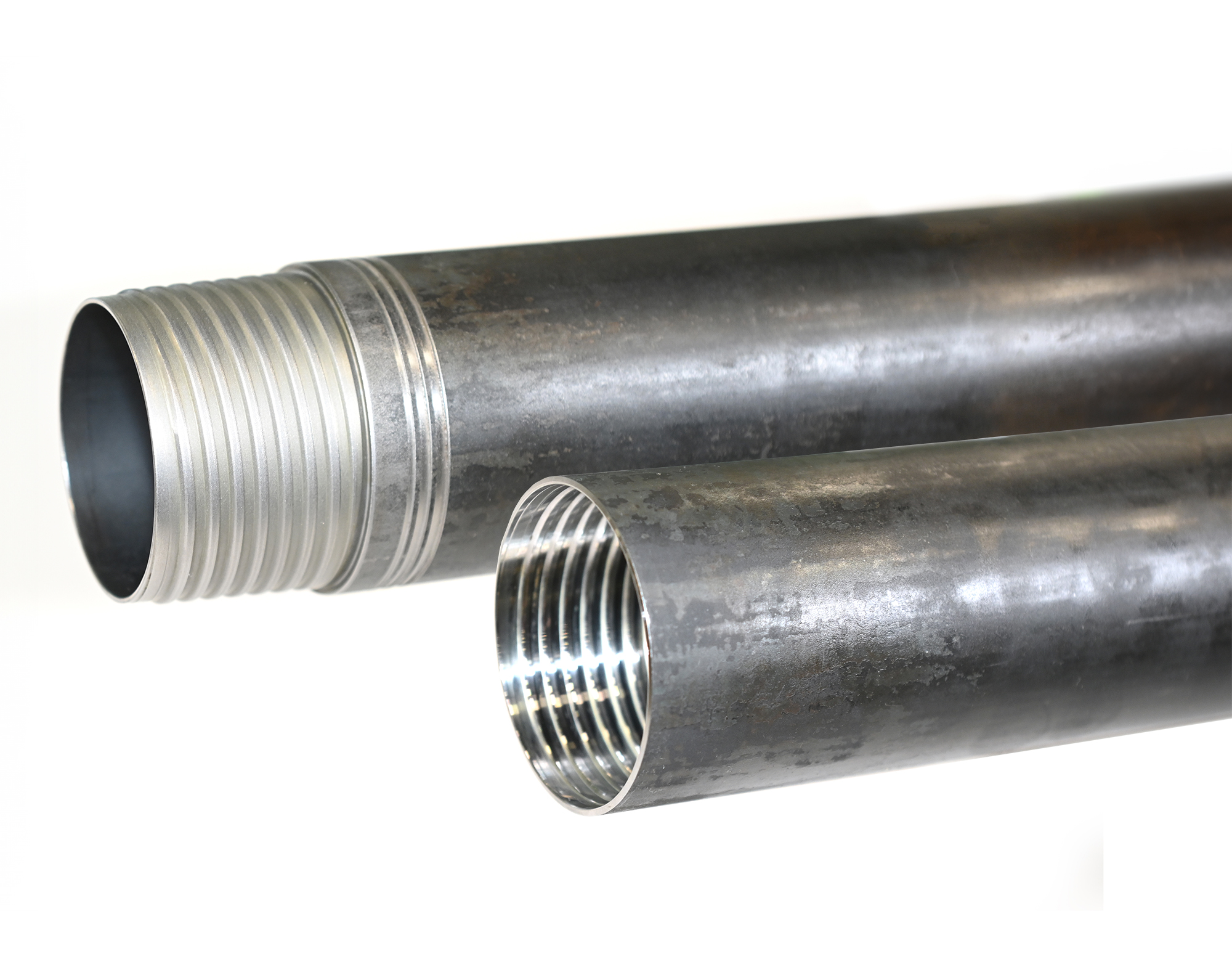

Introducing the next generation wireline drill rods: S-Maxx by Di-Corp. Specifically designed to meet the needs of today’s modern driller, S-Maxx drill rods’ unique dual start thread helps drillers reach greater depths and achieve new limits. With S-Maxx, you gain efficiency by preventing cross-threading – resulting in faster make and breaks. You gain efficiency from more durable rods, resulting in cleaner shifts, reduced downtime, and increased productivity. By investing slightly more in drilling rods, you gain lower cost per meter drilled throughout the project.

Di-Corp spent years designing, researching, developing, improving, and testing the S-Maxx to ensure it was ready to meet the needs of modern drilling and match our high standards for drill rod quality and durability. In doing so, we paired our demonstrated commitment to quality rods found in all Drillers Edge wireline rods with a revolutionary new thread form uniquely capable of delivering unmatched drilling performance.

Max rod life. Max joint strength. Max depth capacity. Max efficiency.

Download the S-Maxx Drill Rod brochure

[English] [Français] [Español]