Following is a reprint of a Coring Magazine article written by Di-Corp Drilling Fluids Manager, Walker Dillabough.

When we consider all the variables that can add to or subtract from the successful completion of a drilling program, one universally stands out: ground condition. Millions of meters of exploration has surely given us a healthy respect for the fact that ground is different everywhere and can vary wildly from hole to hole even, on the same property. Wellbore stability is of prime concern but is a very general term. It can apply to anything from the collaring of a hole in unconsolidated overburden, to intercepting fractured and/or vugular formations thousands of feet below the rig. So, how do you approach a dynamic and fragile ground condition that could cause lost time, core, tooling and data?

The key to hole stabilization is understanding and managing the unique ground conditions that are present at every hole. If one agrees with that, then one must also agree that those who are in the best position to proactively do something are the drillers and drilling assistants working at site. They are responsible for mixing and administering drilling fluids and additives on a daily basis, monitoring the effectiveness and impact on hole stability. It is therefore worthwhile to invest the time and resources in these key people to ensure they have a working understanding of the chemistry involved, the reasons for choosing certain fluids and additives under certain conditions, and the overall effect the fluids can have on the success of the drilling program. After all, they have the most direct influence on the eventual outcome.

As producers of Drillers Edge tooling and Earth Pro drilling fluids, Di-Corp has always taken a different approach to the way we work with our customers. While many companies focus customer support efforts on sending a representative to site once a problem develops, Di-Corp prefer to partner with customers in an effort to reduce concerns before they occur.

Di-Corp’s three-pronged drilling fluids service model focuses on what we call the 3 ‘E’s – Early Identification, Engineer, and Execute. It allows for easy and swift focus on a range of drilling challenges, including hole or wellbore stabilization.

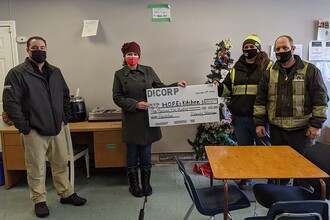

- Early identification and education: the earlier you know about a problem, or the potential for a problem, the better. ‘Early’ equates to before a drill rig is ever mobilized to a site.Previous geological data collection, either from early exploration or known problem ground such as kimberlite should be communicated to a fluids provider as early as possible so that they can provide the best possible suite of fluid additives. Open dialog with the fluids professional ensures preparation. Equipping your on-site team with the right information ahead of time is an often-overlooked opportunity. Di-Corp offer regular on-site and in-shop ‘Mud Schools’ where our drilling fluids experts arm drillers and drilling assistants with vital information to manage fluid effectiveness, mitigate problems, and communicate concerns efficiently.

- Engineer a plan: You aren’t working in your backyard, or twenty minutes from your fluid supplier’s warehouse. Most times, you’re working in the most remote location, with limited seasonal access, and often underground. Telephoning is not always an option, and a fluids professional can’t magically appear on site whenever you need assistance with troubleshooting. Di-Corp has you covered. Using Di-Corp’s ‘Fast Track Fluids Tool’ (FTFT), customers can employ forward thinking and preparation long before a bit hits the ground.The FTFT is a one-page printable document providing insight to every stage of drilling fluid utilization from pre-project planning to real-time problem solving at a drill rig. Each FTFT is customized to the rig, crew, ground conditions, location, products and individual preferences. It also incorporates any products the drilling team will have on site, as well as recipes customized to the mixing set-up and preferences. The FTFT also includes critical information regarding geology, known or expected issues or problems, and detailed solutions that the drillers can employ using only what is readily available on site.

Di-Corp’s FTFT provides drilling contractors with an advantage in the bid process by demonstrating a solid plan to minimize downtime and operate efficiently by devising solutions before problems or issues exist. For drillers, it means no more guess work or waiting – and sometimes for days – for a field technician to diagnose and solve an issue. It equips drillers with the ability to seamlessly solve drilling fluids-related woes. Click here to view a sample FTFT.

- Execute early: reaction speed to changing or deteriorating ground conditions is paramount to success, so it’s advisable to apply the FTFT as soon as a problem is identified. Drillers receive optimal data every 1.50 to 3 m of drilling – so they can pinpoint when a wellbore goes from good to bad, and when to alter the fluids presentation to assist according to the FTFT. Whether the remedy is a bentonite grout application, or switching to a formation binding polymer such as Earth Pro MULTIMIX, access to geological data, a plan, and informed drill hands ensures that problem solving a stabilization issue is as easy as ‘1,2,3’.

Grounded in fundamentals

When wellbore stability issues arise, there are fundamental concerns that every driller and drilling assistant need to make note of.

Wet rock is weak rock. This is repeated throughout Di-Corp mud school sessions. Formations that were overlooked can reappear if continually exposed to penetrating water invasion from drilling fluids. This is especially true of sedimentary rocks such as shale, clay, and sand. The priority is to prevent water from entering rock wherever that rock may be weakened.

Low cost solutions are often the best solutions. Unlike production well drilling, coring teams are typically comfortable to ‘wall-up’ an unstable formation, so long as core continues to be extracted from the ground. Solutions such as grouting or cementing a troublesome weak formation are a great way to assist with stabilizing a wellbore, however, it can be just as easy to squish water-softened bentonite chips into a weakened formation for a quick, low-cost stabilization job. Mud professionals pride themselves on these kinds of simple, solid, and creative fixes. Simple solutions can and do work, and they are so often overlooked.

Address the root cause. Do treat the symptoms, but don’t stop there. Be sure to address the root cause of a wellbore stability problem. Is a shale formation squeezing the rods? If so, add lubricant to keep things moving, while considering chemically treating the shale to prevent water absorption which may have led to the problem in the first place. Solid plans address root causes and mitigate them from the start.

The secret to hole stabilization is knowing the ground and knowing that it can change at every hole. You may already be thinking: “This doesn’t apply to my operation. I’ve been drilling on this property for XX years. I know the ground.” Di-Corp’s approach to drilling fluid supply and service builds on your knowledge. We actively seek it and then we assist in sharing it with driller’s helpers and new drillers who work on your projects, and build it into a drilling fluids plan that will help you put ‘more rock in the box’ every shift. As a key supplier and producer of tooling and fluids for the international mining industry, Di-Corp combines customer knowledge with our own to develop innovative Drillers Edge and Earth Pro products, grounded in real-world experience.

Learn more about Di-Corp’s Drilling Fluids Service Model for Mineral Exploration.